Wire rope cleaners and lubricators are crucial in the field of repair and maintenance, where accuracy is the key. These devices are essential to ensuring a smooth and efficient operation of the cable as well as long-lasting life in various industries. In this article, we delves into the role of lubricating the wire rope and cleaning wires for cable maintenance and cable cleaning, examining their roles along with their benefits and positive impact they can have on overall operational efficiency.

Understanding wire Rope Lubricators

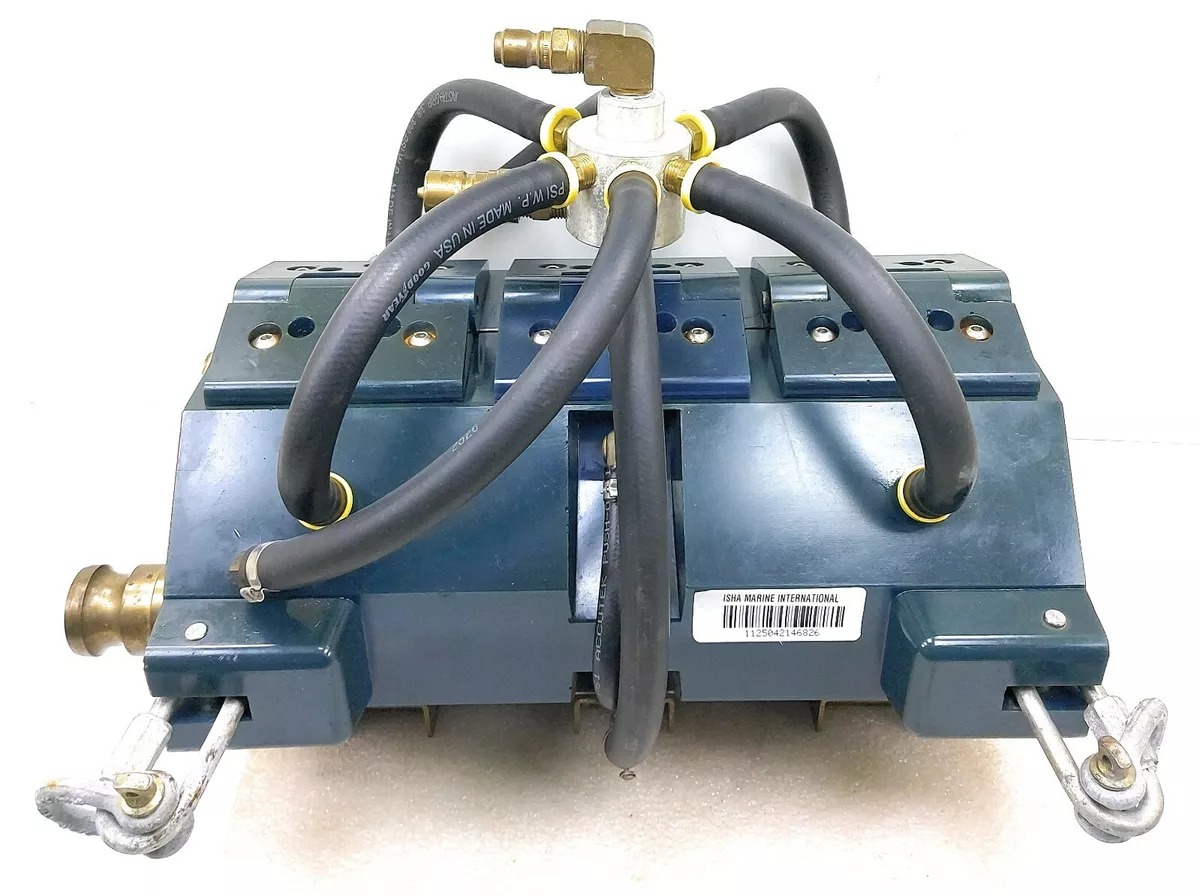

Wire Rope Lubricators are machines designed to ensure that wire ropes are lubricated in an organized method. This process is essential to stop rust from occurring, as well as reducing friction, and enhancing overall endurance. The lubricator will ensure that the lubricant is evenly distributed over the length of the wire rope. This provides comprehensive protection from wear and tear.

The role of wire cleaners in Cable Maintenance:

Parallelly, wire cleaners, also known as cable cleaners, can be instrumental in maintaining the cleanliness of cables. They are specifically designed to eliminate contaminants, debris, and fluids that might build up on the cable during various activities. The use of wire cleaning products is essential in situations where cables are exposed to extreme conditions, which can result in a decrease in performance while avoiding damage. Click here Wire Cleaning

Optimizing Cable Lifespan:

The combination of wire rope lubricators as well as cleaners for wires is a significant factor in increasing the longevity of cables. By using wire rope cleaners to remove contaminants and applying the lubrication process, cables are shielded from harmful effects such as friction, corrosion, or other external elements. This helps preserve the integrity of the cable, leading to improved efficiency and lower maintenance expenses.

Efficiency in the application

Wire rope oilers are created for easy use and efficiency in application. These lubricators are versatile and can be used for various wire rope types and sizes. The methodical and automated application of lubrication assures uniformity that eliminates the danger of inconsistency that manual processes could cause.

In challenging environments, adaptability:

The flexibility of wire rope cleaners and lubricators is vital in the industries that expose cables to harsh conditions. This is the case for drilling, construction, or maritime operations. These tools are built to stand up to harsh environments and offer efficient cable maintenance tools with various situations.

Solutions for maintenance that are cost effective:

An approach that is proactive to the care of cables which includes the use of cables and lubricants, as well as cleaners can be a cost-effective option in the long term. These sophisticated tools cost a tiny amount in comparison to the cost of repair, replacement, and downtime that can result from not taking care of maintenance.

Conclusion:

Lubricators and cleaners for wire wire ropes are the protectors that ensure the integrity of cables as well as accuracy across a broad range of industries. The removal of contaminants and the use of lubricants aids in the long-term preservation and durability of cables. This reduces maintenance and boosts efficiency. Cables are still in use in the most critical sectors, therefore adopting cable maintenance tools that will help ensure reliability and efficiency is vital.